Base metals gained as China’s markets reopened after the Lunar New Year break and traders cheered potentially lower US tariffs.

Copper rallied as much as 2.8% to reach $13,228 a ton in London and aluminum also inched higher. China faces less-punitive charges, a boost for the country’s metal-intensive exports, with the administration proposing a 15% levy after the Supreme Court ruled against President Donald Trump’s reciprocal duties.

“The US Supreme Court dismantled the most cost-effective tariff instrument, but not the new tariff regime overall,” Allianz SE analysts, including chief investment officer Ludovic Subran, wrote in a note. “Uncannily, the Global South and China now emerge as the biggest winners.”

The gains in metals were echoed by a positive tone in mainland equities, as the benchmark CSI 300 Index also advanced on Tuesday. Under the new trade framework — if it’s confirmed — Morgan Stanley estimated that the average US levy on goods from China will drop to 24% from 32%.

The US news is bullish for metals, said Jon Li, an analyst at Guangzhou Finance Holdings Futures Co. Demand from manufacturers will return, he added.

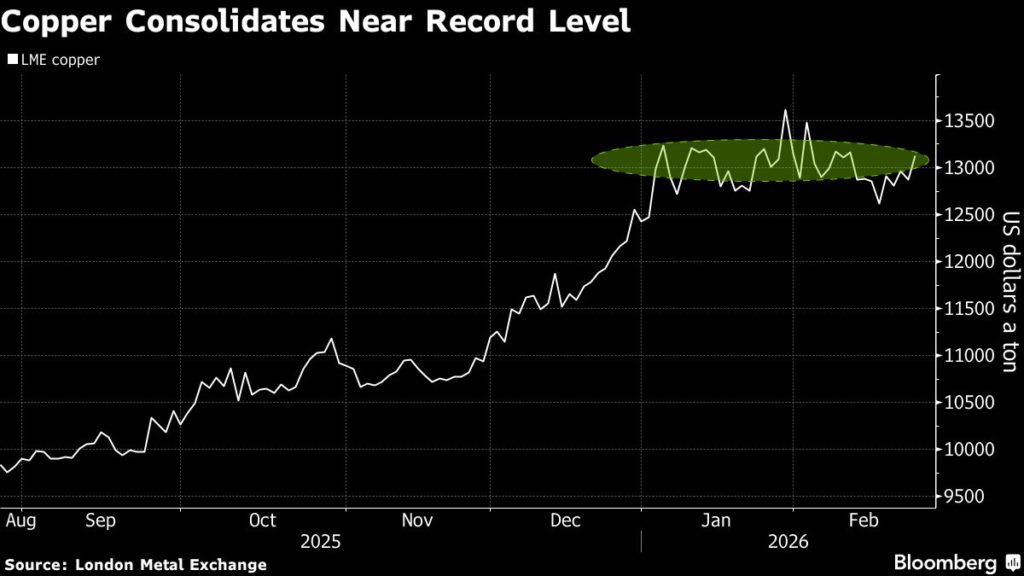

Copper has consolidated at a high level since hitting a record in January, with moves driven by frequent shifts in US policy, as well as mine snarls and forecasts for higher consumption from the energy transition. Higher prices have weighed on physical demand in China, causing exchange-tracked inventories to expand to the highest since 2024. Holdings of the red metal have been rising in the US, as well as in London Metal Exchange-tracked sheds.

Copper rose 2.3% to settle at $13,166.50 a ton on the LME. Aluminum was up 0.1%, as all base metals climbed.

https://www.mining.com/web/copper-price-jumps-as-china-traders-cheer-prospect-of-lower-us-levies/

By City A.M - Feb 25, 2026, 1:00 PM CST

The White House has requested formal pledges from US tech giants that the swelling data centre boom will not drive up electricity bills for households, as concern mounts over AI’s energy demands.

Donald Trump has approached behemoths like Microsoft and Alphabet, who have notoriously rallied behind his administration, about signing voluntary, non-binding agreements committing them to “pay their own way” as they build out new infrastructure.

Most notably, the proposal requests that hyper-scale data centre operators cover 100 per cent of the cost of new power and grid updates needed for their facilities.

Firms will also be asked to sign long-term electricity contracts to make sure other customers are not left exposed if demand does fall flat, or if projects end up failing.

The request aims to combat growing anxiety that AI’s explosive growth, and the ‘braggawatts’ needed to power it, could put even more strain on an already stretched grid.

Federal projections estimate data centre electricity demand could triple between 2025 and 2028, adding additional huge amounts of pressure to creaking regional grids; US electricity prices have soared faster than overall inflation in parts of the country; wholesale power costs are on the rise; and consumer bills have become increasingly political ahead of November’s midterm elections.

Trump campaigned on a pledge to halve electricity prices within 18 months of taking office, yet residential power costs have continued to edge higher.

In a January Truth Social post, the President insisted that while data centres are ‘key’ to the AI build-out, the “big technology companies who build them must pay their own way”.

A voluntary compact

The proposed agreement would not carry the force of law, and the White House has said the draft that is circulating may already have evolved.

However, administration officials say public pledges could add a degree of accountability as well as show voters that the government is keen to stop AI infrastructure from inflating living costs across the country.

Under draft principles reported earlier this month, tech giants would work with federal and state regulators to draw up power agreements that “in every manner possible” hold residential customers harmless.

Beyond electricity pricing, data centre developers will also make sure new sites are “water positive”, mitigate noise and traffic disruption, and support local education and community initiatives.

These pledges land as jurisdictions, including Atlanta and New Orleans, have imposed restrictions on new data centre construction, while more than two dozen projects were reportedly delayed or blocked in January alone amid community opposition.

Microsoft has said it will cover the cost of additional grid infrastructure tied to its data centre plans, while Anthropic recently stated that AI firms “shouldn’t leave American ratepayers to pick up the tab”.

Other operators have fought back, arguing they already pay the full cost of their energy usage and that well-designed tariff structures can protect consumers.

In the UK, Ofgem has launched a review of grid connection queues after receiving more than 50 gigawatts of requests linked to data centre projects, which exceeds Britain’s recent peak daily demand.

The regulator warned that surging applications risk delaying other critical energy projects across the country.

Data centre planning applications hit an all-time high in the UK in 2025, City AM revealed, as investors rushed to gain a foothold in the burgeoning AI market.

More than 60 separate planning applications for the construction of new data centres were filed in England and Wales over the course of the year, according to a City AM analysis of more than 300 local authority planning databases, representing an increase of 63 per cent compared to 2024.

On Wednesday at 10:58 AM (Bangkok time), the share price of PTT Global Chemical Public Company Limited (SET: PTTGC) rose by 4.67% or THB 1.25 to THB 28.00, with a trading value of THB 854.24 million.

The Siam Cement Public Company Limited (SET: SCC) grew by 2.70% or THB 6.00 to THB 228.00, with a trading value of THB 1.63 billion.

Indorama Ventures Public Company Limited (SET: IVL) surged by 3.04% or THB 0.70 to THB 23.70, with a trading value of THB 796.23 million.

IRPC Public Company Limited (SET: IRPC) gained 3.65% or THB 0.05 to THB 1.42, with a trading value of THB 78.48 million.

Kasikorn Securities (KS) highlighted positive developments in the petrochemical sector following the approval of a significant industry restructuring plan by the South Korean government.

According to a Reuters report, South Korea’s Ministry of Industry has sanctioned the merger of olefins plants operated by Lotte Chemical and HD Hyundai. This initiative is supported by a substantial financial package worth $1.3 billion.

The restructuring plan is expected to withdraw about 1.1 million tons of annual production capacity from the market, which aligns with the government’s broader objective to reduce overall capacity by 3-4 million tons.

Additionally, a recent decision by the U.S. Supreme Court to revoke reciprocal tariffs imposed by the Trump administration could spur accelerated restocking activities among U.S. importers. This is likely to lead to a short-term increase in import demand, which should positively impact product spreads, mirroring the favorable conditions seen in the second quarter of 2025.

Kasikorn noted that foreign fund flows into petrochemical stocks remain relatively muted compared to those in the refinery and upstream sectors. This could provide short-term opportunities for speculative trading in Thai petrochemical stocks such as PTTGC, SCC, IVL, and IRPC.

Among these, the brokerage maintains a preference for PTTGC, citing its still-low proportion of foreign ownership.

The UK government announced new sanctions on Russia's so-called shadow oil fleet as it ramped up efforts to squeeze energy revenues funding the Kremlin’s war in Ukraine.

Britain targeted 175 companies in the 2Rivers network, according to a statement from the foreign office on Tuesday which coincided with the fourth anniversary of Russia's full-scale invasion. It also sanctioned PJSC Transneft, one of world’s largest oil pipeline companies, which it said was responsible for transporting over 80 percent of Russia’s oil exports.

"The UK has today taken decisive action to disrupt the critical financing, military equipment and revenue streams that sustain Russia’s aggression," Foreign Secretary Yvette Cooper said in a statement, describing the package as "our largest raft of measures since the early months of the invasion."

Bloomberg in October reported on how the 2Rivers network, linked to Azeri traders Etibar Eyyub and Tahir Garayev, has been instrumental in keeping hundreds of millions of barrels of Russian crude flowing despite international sanctions imposed in response to the war.

The network of offshore companies, previously known as Coral, rapidly grew in stature before sanctions imposed by the European Union and UK since 2024 damaged its ability to operate. At the time, Garayev's lawyers denied that he has any relationship with Rosneft or Eyyub and said he had not been involved in any petroleum-related activities since late 2022. Representatives for Eyyub's companies didn’t respond to a request for comment

The sanctions have had the effect of increasing the cost of each trade and causing Western banks, insurers and professional services firms to largely avoid them so they themselves don't also come under the eye of the authorities, according to people with direct knowledge of the operations.

It's forced the network to pay higher insurance premiums, accept longer and more opaque shipping routes, and reduce its price per barrel as brokers, refiners, storage operators and ports either refused to trade with them entirely or raised costs to protect themselves, the people said.

The foreign office said international sanctions had deprived Russia of some $450 billion of revenue, the equivalent of two more years of funding for its war.

By Staff Writer - February 25, 2026

ZIMBABWE has imposed an immediate ban on exports of all raw minerals and lithium concentrates, said Reuters citing a mines ministry announcement on Wednesday.

Reuters said in its report that the reason for the ban was alleged malpractices and leakages in the country’s export processes.

The suspension applies with immediate effect, including to minerals already in transit, and will remain in place until further notice. “Government expects cooperation of the mining industry on this measure which has been taken in the national interest,” the ministry said.

In a letter to Zimbabwe’s Chamber of Mines, the ministry said the move was intended to “curb leakages and enhance efficiency” in export systems, and that it would use the period to realign export processes. The letter was dated February 17.

The ban brings forward restrictions on lithium concentrate exports that had previously been expected to take effect in 2027 as part of a broader push for domestic processing, said Reuters. Zimbabwe is Africa’s largest producer of the battery mineral, exporting 1,128 million tons of lithium-bearing spodumene concentrate in the year to December 2025, up 11% on the previous year.

The country has rapidly expanded lithium output following substantial investment by Chinese mining companies including Zhejiang Huayou Cobalt, Sinomine, Chengxin Lithium Group and Yahua. Most of the concentrate is shipped to China for processing into battery-grade materials, but Harare has been pressing miners to conduct more processing locally to capture greater value from the global energy transition.

Some Chinese firms have already moved in that direction. Huayou recently commissioned a $400m plant to process lithium concentrates into lithium sulphate, while Sinomine has announced plans for a $500m sulphate facility at its Bikita mine. The export ban is likely to accelerate pressure on remaining producers to follow suit.

WASHINGTON, D.C. (RFD NEWS) — U.S. grain export inspections strengthened last week, led by corn and wheat shipments, while soybean volumes eased from recent highs. The USDA reported 3.41 million metric tons of grain inspected for export during the week ending February 19 — up 40 percent from a year ago.

Corn inspections reached 2.01 million metric tons, 6 percent above last year and pushing marketing-year totals to 37.7 million metric tons — sharply ahead of last year’s pace. Mexico, Japan, Colombia, and China were key buyers.

Soybean inspections totaled 669,865 metric tons, down from the prior week and well below year-ago levels. Marketing-year soybean exports now stand at 25.0 million metric tons, trailing last year’s 36.9 million metric tons pace. China remained the top destination, with significant volumes also moving to Mexico, Egypt, and Southeast Asia.

Wheat inspections reached 535,113 metric tons, up 37 percent from last year. Marketing-year wheat exports total 18.2 million metric tons, running ahead of last year. Pacific Northwest ports handled the largest share, particularly soft white and hard red winter wheat shipments to Asia.

Sorghum exports remained firm at 200,287 metric tons, largely to China.

Farm-Level Takeaway: Corn export pace remains the bright spot, but stable ethanol export demand remains a critical support for corn markets.

Global Ethanol Trade Strengthens Corn Demand and Margins

Strong international fuel demand and late-year shipment growth pushed U.S. ethanol exports to record levels in 2025, reinforcing corn usage across rural production regions. Renewable Fuels Association data shows exports totaled 2.18 billion gallons shipped to more than 80 countries, up 13 percent from the previous year.

Export value reached $4.8 billion and $7.6 billion, including coproducts. December shipments alone climbed 4 percent to 220.3 million gallons — the second-largest monthly total on record — highlighting steady overseas reliance on U.S. supply. Canada remained the top buyer, followed by the European Union, India, the United Kingdom, and Colombia, while markets such as Jamaica, the Philippines, and Brazil expanded their purchases. The United States imported only about 4 million gallons, maintaining its status as a net exporter for the sixteenth consecutive year.

Exports of dried distillers’ grains (DDGS) totaled 11.6 million metric tons valued at $2.8 billion. Mexico led buying, with Indonesia, South Korea, and Vietnam also major markets despite late-year fluctuations.

Strong export activity helps stabilize ethanol plant utilization and supports corn grind even when domestic blending shifts.

Seabridge Gold Stock Performance

Seabridge Gold Inc. (TSE:SEA)'s stock price reached a new 52-week high during trading on Wednesday . The company traded as high as C$52.48 and last traded at C$52.05, with a volume of 8355 shares. The stock had previously closed at C$51.29.

The company has a quick ratio of 3.34, a current ratio of 2.28 and a debt-to-equity ratio of 58.83. The firm has a market capitalization of C$5.54 billion, a price-to-earnings ratio of -94.60 and a beta of 1.84. The company has a 50-day moving average price of C$43.76 and a 200-day moving average price of C$35.91.

Insider Transactions at Seabridge Gold

In other news, insider Elizabeth K. Fillatre Miller sold 1,648 shares of the business's stock in a transaction dated Monday, January 5th. The stock was sold at an average price of C$40.49, for a total value of C$66,727.52. Following the sale, the insider directly owned 32,969 shares in the company, valued at C$1,334,914.81. The trade was a 4.76% decrease in their ownership of the stock. Company insiders own 2.78% of the company's stock.

Seabridge Gold Company Profile

Seabridge holds a 100% interest in several North American gold projects. Seabridge's principal asset, the KSM project, and its Iskut projects are located in Northwest British Columbia, Canada's " Golden Triangle ", the Courageous Lake project is in Canada's Northwest Territories, the Snowstorm project in the Getchell Gold Belt of Northern Nevada and the 3 Aces project is in the Yukon Territory.

Freeport-McMoRan Inc. (NYSE:FCX) is one of the Best Stocks to Buy and Hold For the Next 3 Years. On February 18, Freeport-McMoRan Inc. (NYSE:FCX) announced signing a Memorandum of Understanding with the Government of Indonesia to extend its mining operations at the high-value Grasberg minerals district indefinitely, based on the site’s resource lifespan.

Management noted that this agreement extends long-term access of its subsidiary, PT Freeport Indonesia (PTFI), to one of the world’s largest copper and gold deposits. The terms of the agreement note that PTFI will increase its community investment and will fund a new hospital and two medical training facilities.

Pixabay/Public Domain

Moreover, as part of this MoU, Freeport-McMoRan Inc. (NYSE:FCX) retains 48.76% ownership in PTFI through 2041, after which the company will transfer 12% to the government at book value. Richard C. Adkerson, Chairman of the Board, noted:

“We value our long-standing partnership with the Indonesian government, the people of Indonesia and Papua, and the mutual trust that has been built over many years. The Grasberg operations have provided substantial benefits to all stakeholders over their six-decade history, and this extension will provide opportunities to continue to build substantial value for all stakeholders in one of the world’s most significant copper and gold deposits.”

Freeport-McMoRan Inc. (NYSE:FCX) is involved in the mining of copper, molybdenum, and gold. The company’s operations are divided into the following segments: North America Copper Mines, South America Operations, Indonesia Operations, Molybdenum Mines, Rod and Refining, Atlantic Copper Smelting and Refining, and Corporate and Other.

While we acknowledge the potential of FCX as an investment, we believe certain AI stocks offer greater upside potential and carry less downside risk. If you’re looking for an extremely undervalued AI stock that also stands to benefit significantly from Trump-era tariffs and the onshoring trend, see our free report on the best short-term AI stock.

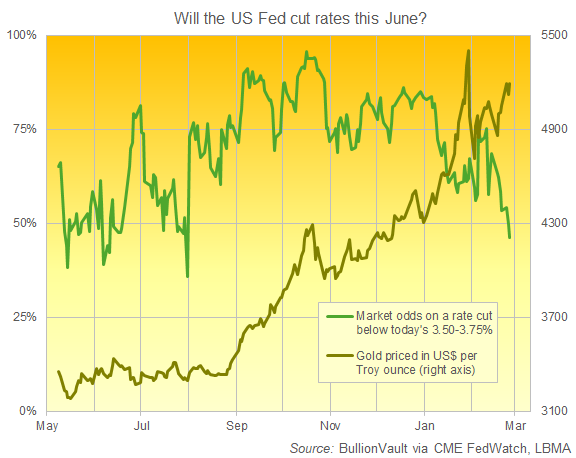

SILVER and GOLD rallied again on Wednesday, trading at what were new all-time highs only 6 and 4 weeks ago respectively despite betting on US interest rates pushing back market expectations for a Fed cut from June to July following 'hawkish' comments from 3 regional Fed presidents.

Last time that the CME derivatives exchange's FedWatch tool said interest-rate traders didn't expect this June's meeting to end with a lower cost of borrowing than now was in late July.

The price of gold was then trading almost $2000 per Troy ounce below today.

That was just before the 'Friday chaos' in gold and other financial markets of 1st August, when US President Trump rolled out the heaviest import tariffs since the Great Depression while shockingly weak jobs data sent the odds of Federal Reserve rate cuts soaring.

Across 2025, the price of gold in US Dollars moved in the same direction as the odds of Fed rates being lower than today in June 60.0% of the time on a 5-session basis.

That has sunk to 35.1% of the time so far in 2026.

"Chicago Fed's [Austin] Goolsbee throws cold water on rate cuts," says a headline at Barron's magazine after one of the Federal Reserve's leading but non-voting members for 2026 said in a speech that "we stopped making progress on inflation" last year.

"With inflation at 3%" but the Fed's target at 2%, that "is not good enough."

"It'll be appropriate to hold in the current range for some time," said Boston Fed President Susan Collins in separate remarks.

Interest rates at the current 3.50% to 3.75% are "well positioned" agreed Richmond Fed President Tom Barkin, also not a voting member of the FOMC policy committee this year.

Spot gold prices in London's bullion market today touched $5200 per Troy ounce, showing a 2.7% rise for the week so far.

Silver meantime rose back above $90 per ounce, touching a 3-week high but still trading over 25% below end-January's record-high precious metals price spike.

"Despite [last Friday's] disappointing ruling, these powerful, country-saving...tariffs will remain in place under fully approved and tested alternative legal statutes," said US President Trump in his record-long State of the Union address to Congress last night, rebuking the Supreme Court's decision to over-turn the "emergency" import duties imposed by the White House last year.

"We're not going to see tariff relief in the longer run, and businesses know that," reckons Mary Lovely, a senior fellow at the Peterson Institute for International Economics in Washington.

https://www.bullionvault.com/gold-news/gold-price-news/silver-gold-fed-rates-022520261

Business South African mining giant doubles profits after being kicked to the curb by Anglo American Luke Fraser · 25 Feb 2026

Valterra Platinum has seen its profit double following its unbundling from Anglo American last year.

Last year, Anglo American unbundled Valterra, then Anglo American Platinum, as part of a restructuring to stave off a takeover bid from BHP.

Anglo American decided to reduce its exposure to South Africa but kept Kumba Iron Ore. Anglo is also currently in advanced merger negotiations with Canada’s Teck Resources over a possible merger.

The demerger caused a massive capital outflow from South Africa. However, platinum group metals (PGMs) saw enormous price increases in 2025 amid supply constraints and questions over the transition to electric vehicles.

PGMs, which South Africa accounts for 80% of the world’s total supply, are primarily used in catalytic converters in cars with engines to minimise emissions.

‘2025 was a defining year for our company, with the successful demerger from Anglo American plc, our launch as Valterra Platinum, and our secondary listing on the London Stock Exchange,” said CEO Craig Miller.

While sales declined by 15% over the period, the group benefited from a 22% increase in rand price per ounce sold to R32,611.

Miller noted that the group’s EBITDA increased 68% to R33.4 billion, supported by a 22% increase in the rand basket price and R5 billion of additional cost reductions.

The group’s basic earnings rose to 117% to R15.4 billion over the period, while headline earnings rose 98% to R16.7 billion.

The group declared a final dividend of R11.5 billion, or R43 per share. This includes a R6.2 billion dividend, or R23 per share, which is 40% of headline earnings.

The group also declared a special dividend of R5.3 billion or R20 per share. The group’s total dividend for the year was R12 billion, or R45 per share, with a payout ratio of 71%.

The large payout to shareholders comes two years after the group announced a restructuring, where it laid off over 3,000 employees.

Citi leans bullish despite acknowledging price direction remains uncertain, citing multiple tailwinds converging in coming months.

Copper could reach $14,000 per tonne within three months, driven by Chinese supply-chain restocking after Lunar New Year holidays and continued dip-buying from investors, according to Citi's latest commodities note.

The bank sees a "bullish risk-reward skew" despite difficulty calling price direction with conviction. Three key factors support upside: investor appetite to price in cyclical growth optimism, increasing hard asset exposure tied to 'de-dollarisation' and resource security themes, and potential supply disappointments.

China's post-holiday restocking typically provides seasonal support

Chinese manufacturers returning from CNY holidays have historically created demand spikes as factories rebuild inventories. This year's restocking phase coincides with broader investor interest in commodities as inflation hedges and dollar alternatives.

Citi maintains its $13,000 per tonne average forecast for 2026, unchanged from previous guidance. The bank believes this level will broadly balance global physical copper markets throughout the year, though near-term momentum could push prices higher before settling.

Supply disruptions remain a wild card that could accelerate gains beyond current projections.

https://finance.yahoo.com/news/copper-prices-set-touch-14-161504621.html

SOURCE: Mining.com | February 25, 2026

Ionic — which is advancing a large rare earths deposit at its Silicon Ridge property — is eyeing an IPO as early as next year and has hired Citigroup to help with the listing process.

The proposed move comes just weeks after the company confirmed the Silicon Ridge discovery, calling it one of “North America’s most significant” finds to date. The deposit, it said, hosts a suite of rare earth elements as well as many other critical minerals such as gallium, germanium and tungsten.

In a December 2025 news release, Ionic noted that its project is currently fully permitted and shovel-ready, and would benefit from an existing processing facility located in Provo, where the company is headquartered.

2027 IPO

Speaking to Bloomberg, its CEO Andre Zeitoun said that the company intends to secure offtake agreements and scaleup funding before proceeding with the listing.

“From there, we’re looking at a 2027 IPO,” he said.

Ionic is considering the move as the US ramps up efforts to establish a critical minerals supply chain that is independent of China. Earlier this week, the Trump administration unveiled plans for a $12 billion stockpile of critical minerals. Vice President JD Vance followed that up by announcing plans to marshal allies into a preferential trade bloc for critical minerals.

“We have a domestic, shovel-ready source for a full spectrum of critical minerals, all extractable with a faster, cleaner process than traditional hard rock mining and extraction,” Zeitoun told Bloomberg.

‘Significant’ deposit

According to Ionic, the Silicon Ridge deposit is hosted on an ion-adsorption clay (IAC) system, which, compared to the conventional “hard-rock” geological system, is easier to extract minerals from, and is the same geological formation that supplies approximately 35-40% of China’s total rare earth production.

Speaking to the Wall Street Journal in December, Zeitoun said its project “may be the most significant critical mineral reserve in the US,” as it hosts as many as 16 different elements used in key applications, ranging from AI semiconductor chips and permanent magnets to defense surveillance systems and energy technologies.

The company has said it plans to release an economic assessment for the Silicon Ridge project during the first half of 2026.

https://aggregatesandminingtoday.com/2026/02/utah-rare-earth-miner-ionic-eyes-ipo-in-2027-2/

This move is likely to slow down the seasonal accumulation of steel product stocks

Some Chinese steel producers in the north of the country will have to cut production from March 4 to ensure air quality during the annual parliamentary session (National People’s Congress), which is a customary step. This was reported by Reuters with reference to analysts and consulting companies.

According to Mysteel, several steel mills in northern China have been notified of a voluntary start to controls that will reduce blast furnace production by at least 30% between March 4 and 11.

Xin Ge, deputy director of consulting firm Lange Steel, noted that this move is likely to help slow the seasonal accumulation of steel inventories, supporting steel prices. He said higher steel prices, combined with expectations of stimulus measures after the meeting, would encourage mills to replenish raw material stocks for the next production ramp-up.

Demand for steel in China usually increases in March, as warm weather contributes to the resumption of construction activity.

It should be noted that steel production in China fell below 1 billion tons last year, reaching its lowest level since 2018. According to the National Bureau of Statistics of China, the country produced 960.81 million tons of steel last year, down 4.4% year-on-year. The decline was the result of a protracted crisis in the real estate market, which significantly limited domestic demand for steel products.

https://gmk.center/en/news/china-urges-steelmakers-to-cut-production-in-northern-part-of-country/

All deliveries were of Polish products

In January 2026, Ukrainian steel enterprises increased imports of coke and semi-coke (UKTZED 2704) by 18.8% compared to the previous month, to 68.96 thousand tons. Compared to the same period in 2025, volumes decreased by 25,7%. This is evidenced by GMK Center calculations based on data from the State Customs Service.

All supplies for the year came from Poland. The cost of raw material imports for the month increased by 14.3% month-on-month and decreased by 21% year-on-year, to $23.62 million.

Between 2013 and 2024, coking coal production in Ukraine fell by 74%, and coke production by almost 85%. Most of the mines and coke chemical plants remained in uncontrolled territories – 64% of the total number.

According to GMK Center estimates, to maintain production at the current level, namely 6.5 million tons of steel produced by converter and open-hearth methods and 1.3 million tons of commercial pig iron, Ukraine needs 3.2 million tons of coke per year, of which up to 20% was imported in 2024.

In early April 2025, the first ship with coking coal from the US, chartered by the Metinvest Group, arrived in Ukraine. The bulk carrier delivered 80,000 tons of raw materials from the United Coal Company, which is part of the group. Metinvest planned to carry out similar import deliveries on a monthly basis.

It should be noted that in 2025, Ukraine imported 700,650 tons of coke and semi-coke, which is 5.9% more than in 2024. The bulk of the year’s supplies came from Poland – 657,840 tons. Another 27.67 thousand tons of coke were imported from Indonesia and 15.08 thousand tons from the Czech Republic. Raw material import costs increased by 1.4% year-on-year to $238.66 million.

https://gmk.center/en/news/ukraine-imported-69-000-tons-of-coke-in-january/